Process

All of my work begins with a block of raw glass that has been cast to rough form in the kiln.

My casting forms are purpose built out of either stainless steel sheet or high fire ceramic slab - two materials that will maintain their integrity at the high temperatures required for melting glass.

The casting forms are placed in the kiln and loaded with blocks of raw colored glass. As the kiln nears its target temperature of 1600*F, the glass begins to flow and melt to fill the casting form. The glass will stay at this temperature for several hours to allow any large bubbles to rise to the surface and pop. Next comes the long, slow cooling phase.

Most pieces will spend about 200 hours in the kiln. When glass changes temperature too quickly it takes on massive stress that will eventually cause it crack, so the kiln is cooled extremely slowly, just a few degrees per hour. Once it’s reached room temperature again, these new blocks of raw glass come out of the kiln gnarly and rough.

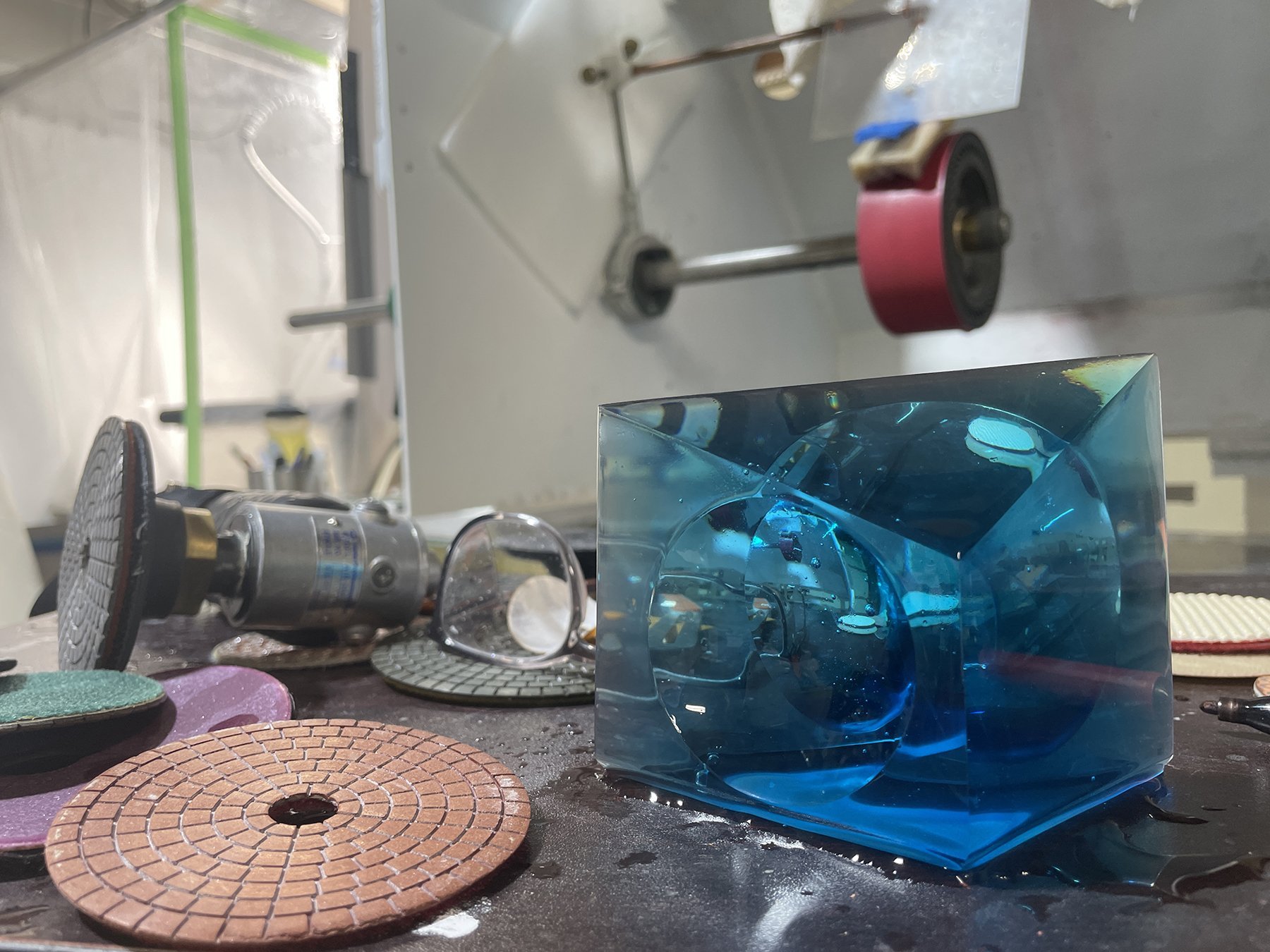

This is when shaping can begin. Most pieces start on the wet saw, as I begin to rough out a basic form. From there, grinding and shaping continues with a variety of diamond tools.

01.

A block of raw green optical crystal is mounted on a studio-built belt driven turntable as rough shaping begins. This allows the work to be locked into one position, ensuring that the glass is rotating on a fixed axis — allowing for perfectly concentric rings and lenses to be carved into the surface.

02.

Fine grinding of lens and concentric grooves finished on first side.

03.

A diamond wheel with a convex profile is mounted in the handheld grinder. As the piece spins, grooves and lenses are carved into the surface of the glass.

04.

Fine grinding of first hemisphere done, ready to be mounted on turntable for work on second hemisphere to begin.

05.

Rough carving of grooves on the second hemisphere is completed. The surface is ready for refining with a smoother diamond wheel.

06.

After the contours of the piece have been established and refined with successively finer diamond grinding wheels, the surfaces are smoothed with wheels and pads that bring the glass closer go a polish. This wheel is made of rubber embedded with aluminum oxide grit, and leaves the glass with a satin finish that’s ready for final polishing.

07.

The completed prismatic sculpture.